Inflatables

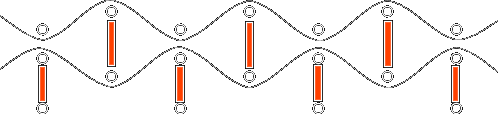

Pleated structures also lends themselves to inflation - as

illustrated in the following diagrams:

|

| Simple inflation of two membranes

|

Inflation helps create a curved surface - which is desirable

from the point of view of creating a maximally-stable

structure.

Inflated surfaces look quite a lot like pleated surfaces -

and inflation on its own solves some of the same problems

pleating does.

For example, the lack of horizontal surfaces helps prevent

pooling in both patterns.

However pleating still offers advantages to buildings with

inflated skins.

|

| Inflation of bladders between two membranes

|

|

| Relatively small bladders would still create an air gap

|

The main idea of using bladders is to divorce structural

components that need to resist the wind and rain from the

elements that should be airtight.

The external membrane offers protection to the bladder,

prevents punctures - and helps make modular replacements

cost-effective.

Layers

An alternative to inflation is a multi-layer structure.

Assuming that regular strut support for the cables is being

used, there are two main patterns for these:

|

| Ridge to ridge, valley to valley

|

This structure is of uniform thickness - but the upper

struts bear down on the lower cables and struts through the

fabric - and there's no terribly neat way of attaching

them.

|

| Ridge to ridge, valley to valley

|

Here no forces are applied by the struts through the fabric

- but the cavity is not of uniform thickness - and the upper

struts bear down on the lower valley cable, increasing the

strain that exerts on the fabric in a manner that may be

undesirable.

In either case, it may be desirable to dehumidify the region

between the layers - in order to minimise condensation

problems there.

Fillings

If two membranes are used there are possibilities for filling

the cavity between them with something other than air.

One possiblity is solidifying structural foam. This creates

an opaque, strong insulating barrier.

Another possibility is to use the pleated membranes as a mould

for concrete.

Having the structural role in pleated structures played by

cables allows them to carry considerable weight.

Letting each layer of concrete set before applying the next

reduces the need for the cables and membrane to support the

weight - since the set concrete is self supporting.

It looks as though dual cable-supported pleated membranes

may well come to present an attractive alternative to

existing concrete mould technologies in some cases.

After construction, the membrane and cables would be removed.

|